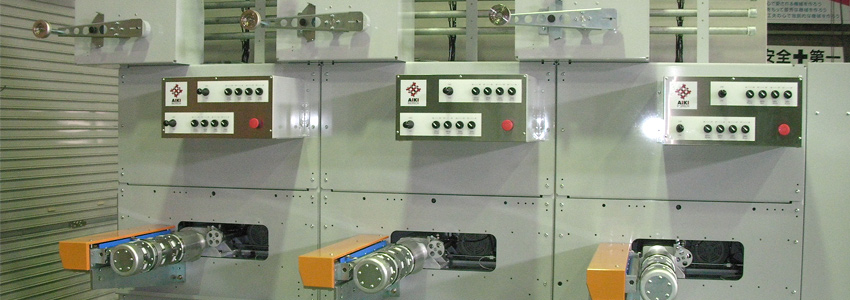

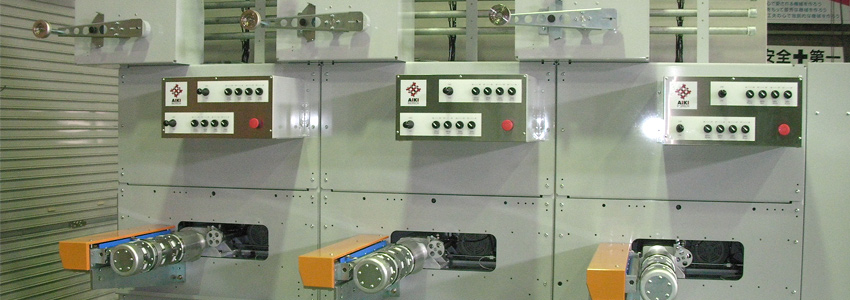

This winder is for PAN precursor which use in the first line process of producing

Carbon Fiber with original AIKI accumulated technology, capable to make desire package. |

| |

|

| Features of APW Series |

|

| a) |

Automatic tension control system with dancer roller :

No need to adjust tension spring or volume to maintain the tension of each positions.

Regarding winding tension, it is possible to choose Uniform tension system or Electronic

tension reduction system on touch panel screen. Combination of dancer roller,

AIKI original torque motor and inverter enable automatic winding tension control. |

|

| b) |

Simple setting :

Able to control all positions, only require to input desired tension and speed to

touch panel screen on main controller. |

|

| c) |

Contact pressure change; Can be selected alternative as follows,

Mechanical system - Able to select contact pressure as user requested by spring adjustment. And able to mecanical decrease gradually.

Electrical system - Able to adjust all positions simultaneously by air-cylinder contorol. Suitable to large package size as well as normal. |

|

| d) |

Production control ( Yarn length, doffing time and yarn breakage ) :

All items can be set & checked by monitor on main controller. |

|

| e) |

Electric Winding ratio change system :

Able to set desired winding ratio by touch panel on main controller before start winding. |

|

| |

| [ Option ] |

|

| a) |

Uniformed winding angle system :

Available with optional. Able to wind with uniformed traverse angle from the biggining to

the end of winding including edge breaker and creeping system. |