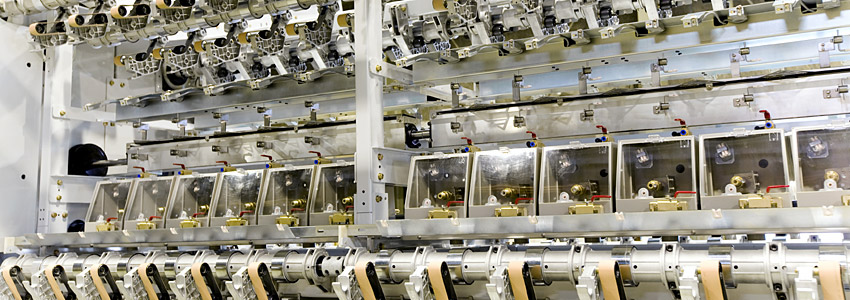

The air texturizing machine has the following functions: it

feeds continuous fibers (POY/FDY) such as nylon and polyester into an air

texturizing nozzle with a feed roller set at arbitrary speed, interlaces

that yarn with air or blends them using turbulence generated by compressed

air inside the nozzle, and then produces yarn known as ATY.

The AT-501 series can produce high-quality ATY stably at high speed. Moreover,

application of an auto-doffing device allows less manpower to be needed

and for the yarn to be maintained at the specified length. These features

suit application to warp yarn. Special yarn such as differential shrinkage

yarn for use in peachskin-like fabrics and slub yarn (knubbed yarn) for

splash-pattern fabrics can also be produced depending on the specifications

of the machine used.

Nylon ATY is often used in sportswear, umbrellas and bags. Spun-like nylon

yarn is mass-produced in Taiwan and South Korea.

Fabric woven with this yarn has been utilized in famous sports brands and

is well-known all over the world. In the polyester field, ATY is being used

in the interior of vehicles such as car sheeting and as materials for interior

decorating by European, Japanese and other global automobile and interior

material manufacturers in recent years. As described, ATY is extremely versatile

due to its variety of forms and characteristics. Demand for ATY also seems

to be expanding due to the possible development of new products differing

from traditional DTY (Draw Textured Yarn).

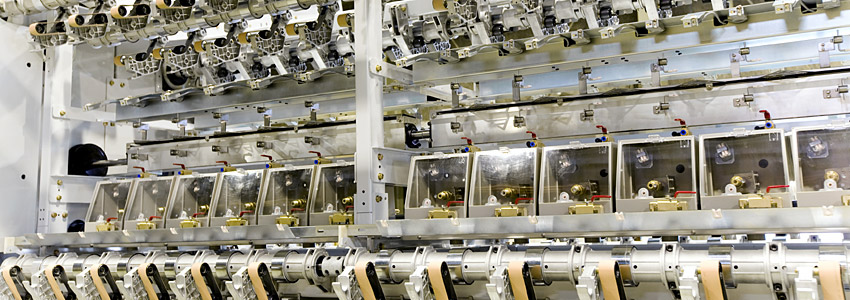

Aiming for even higher yarn quality and work efficiency out of a standard model with an established reputation,

we started development in 2018 and completed the new series (R series) in 2020.

In conjunction with this, we renewed AD into a space-saving built-in type AD which will be shipped from 2021. |