| a) |

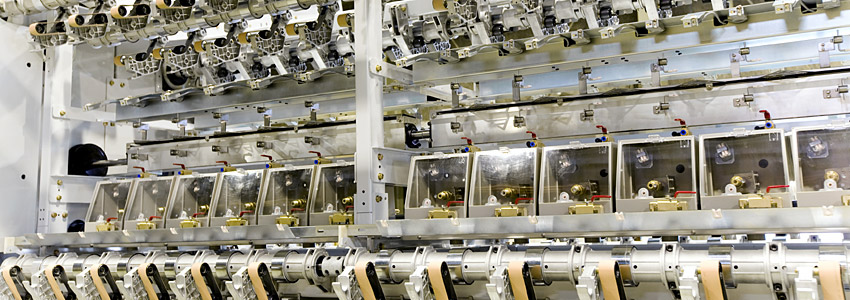

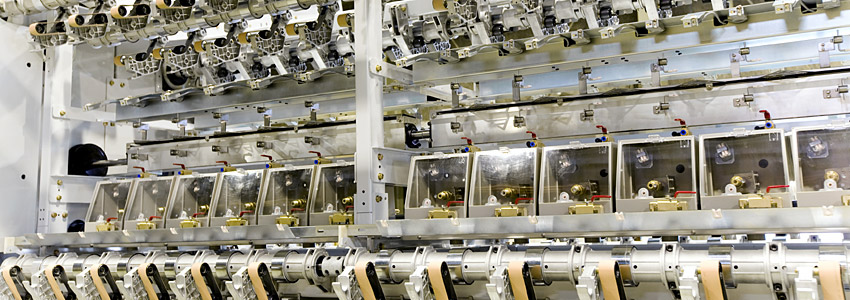

Equipped with five feed rollers and a hot pin heater. ATY is produced with compressed air by using POY and FDY of continuous synthetic fibers such as nylon and polyester. |

|

| b) |

T&T yarn can be produced with the hot pin heater and first heater. |

|

| c) |

Differential shrinkage yarn can be produced with the first heater. |

|

| d) |

ATY elongation and size of loop can be adjusted with the second heater. |

|

| e) |

All processing conditions are determined by PLC.

Setting can be carried out with touch panel. |

|

| f) |

Either side (R and L) of the machine can operate independently in different conditions. |

|

| g) |

Utilizes a line shaft driving system, allowing for uniform spindle quality. |

|

| h) |

Winding size is selectable from either 8 inches (200mm) or 10 inches (250mm) |

|

| i) |

The maximum number of spindles is 240. Extending spindles is available by every 24 spindles (one block). |