| a) |

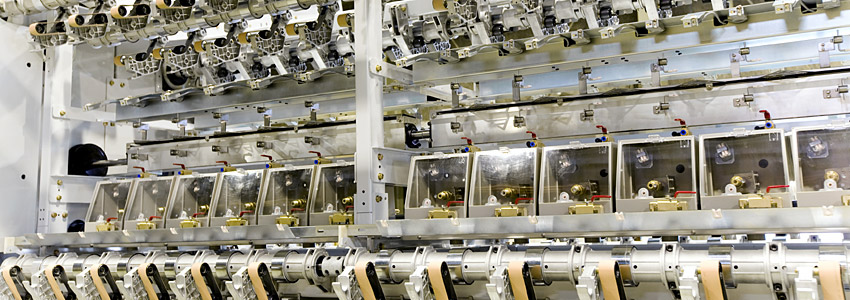

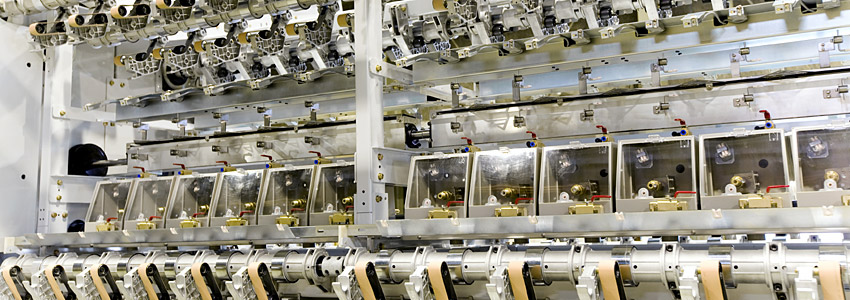

Equipped with four adjustable-speed hot rollers (Φ110mm) per spindle.

POY and FDY of continuous synthetic fibers such as nylon and polyester can be supplied.

Orientation by the hot roller is utilized, allowing for stable orientation of thicker raw yarn than that produced with the shaft driving system. |

|

| b) |

Orientation with the hot roller allows the yarn produced to have very little shrinkage in boiling water. |

|

| c) |

Size of ATY loop can be adjusted with the 2,000mm second heater. |

|

| d) |

All processing conditions are determined by PLC. Setting can be carried out with touch panel. |

|

| e) |

Since an individual driving system is utilized, a wide variety of products in small lots can be produced. |

|

| f) |

Winding size is 10 inches (250mm) with the auto doffer included as standard. |

|

| g) |

Maximum number of spindles per controller is 48. |

|

| h) |

Mainly suitable for the production of ATY as industrial material for use in vehicles and as an interior fabric. |