| a) |

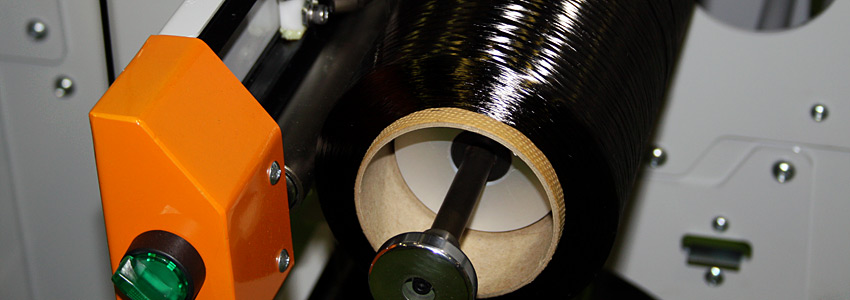

Equipped auto-changer in each position and because of automatically change the bobbins when it

comes the end of doff, reduce manpower and keep the stability of fabric. |

|

| b) |

Taking 4 layer winding system and able to change dimention of bobbins and arrangement as same as

ASFW-R5 type. |

|

| |

Generally, following steps are the production process of Carbon fibers. |

|

1) Supply raw materials (PAN precursor) → 2) Stabiliation (250〜350℃ within air) →

3) Carbonization (1,000〜1,500℃ within Inactive gas) →

4) Surface and sizing treatment → 5) Winding (Carbon fiber) |

|

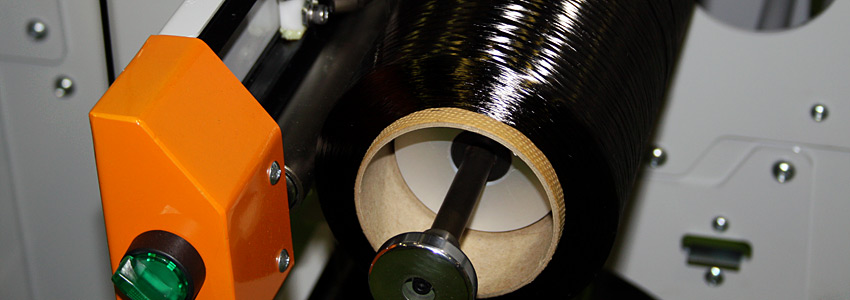

AIKI is producing 1) Winder for precursor and Creel for supply raw materials(precursor),

5) Winder for carbon fiber & tension control devices (feed roller device) within each process.

Install ASFC series for supplying raw materials, ASFW series (please refer separate catalog) for winding,

and AIKI feed rollers within each process will construct stable production line for carbon fiber. |